Custom Fabrication

The 6-Step Process to Custom Fabrication

You have the best invention for a piece of food processing equipment that would streamline your company’s workflow and increase productivity.

But the design isn’t fleshed out, and you’re unsure about the next step.

01. Bring us your idea

Have a bright idea for a new design? Meet with us to discuss options.

02. Brainstorm

03. Design

04. Approval

05. Build

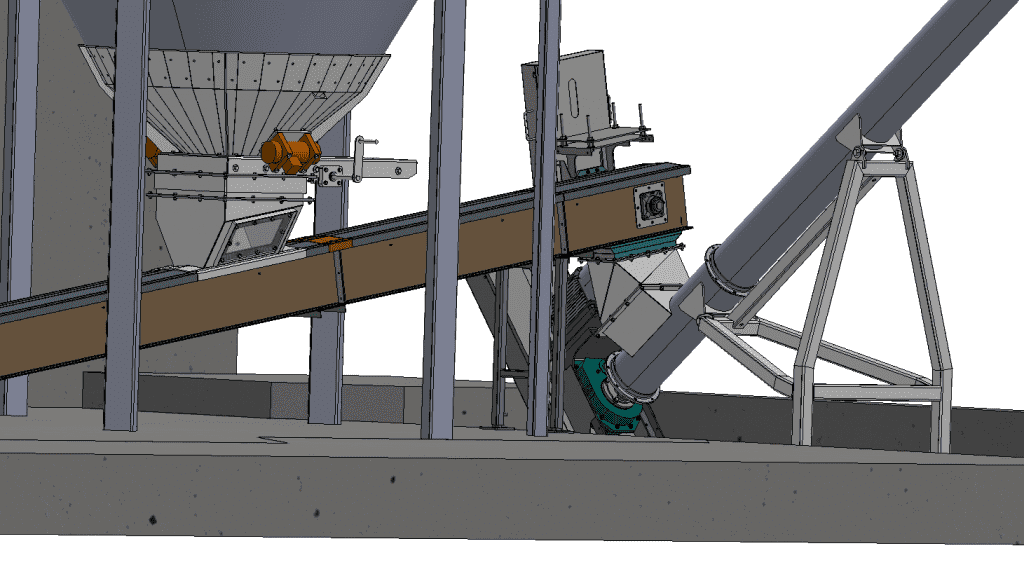

The finalized drawings are then used by our shop fabricators to convert your design from paper to reality.

06. Install

What’s SOLIDWORKS?

Why is SOLIDWORKS a game-changer? Because:

Every measurement is precise

Unlike a physical sketch, a computer-rendered 3D model is accurate to a fraction of a millimetre. Your design is mapped out with mathematical precision.

Not only that, but our water cutting machine is computer-aided, creating cuts that are virtually perfect.

Designs are perfected before fabrication begins

This is beneficial to your custom fabrication for 2 reasons:

B. Alterations are easier – having a 3D rendering lets you see the product on the screen before it’s fabbed, allowing for changes without remaking an entire part.

Concerned About Your Trade Secrets?

We get it — you want your company’s proprietary information to stay secret.

We take confidentiality seriously. This is why we always sign an NDA if requested. No questions asked.

But what if my company’s confidential design could help another company? Will RMS share the information?

Here’s the scenario:

- Customer A has a design already in place. It’s confidential and bound by an NDA.

- Customer B comes into our shop, requesting a similar design.

- RMS faces a problem with an easy, accessible solution.

We could recycle the design to make our own jobs easier. So you’re asking, will we use your confidential information?

The answer is NO. RMS doesn’t share information bound by an NDA contract. It’s that simple.

It’s a sticky scenario. However, it’s not as scary as you’d think, for 2 reasons:

01. Designs are almost never the same

Designs protected by NDAs are complex and require custom fabrication. We rarely come across similar designs.

02. We can find another solution

However, if the unthinkable happens, rest assured: your confidentiality is always our #1 priority.